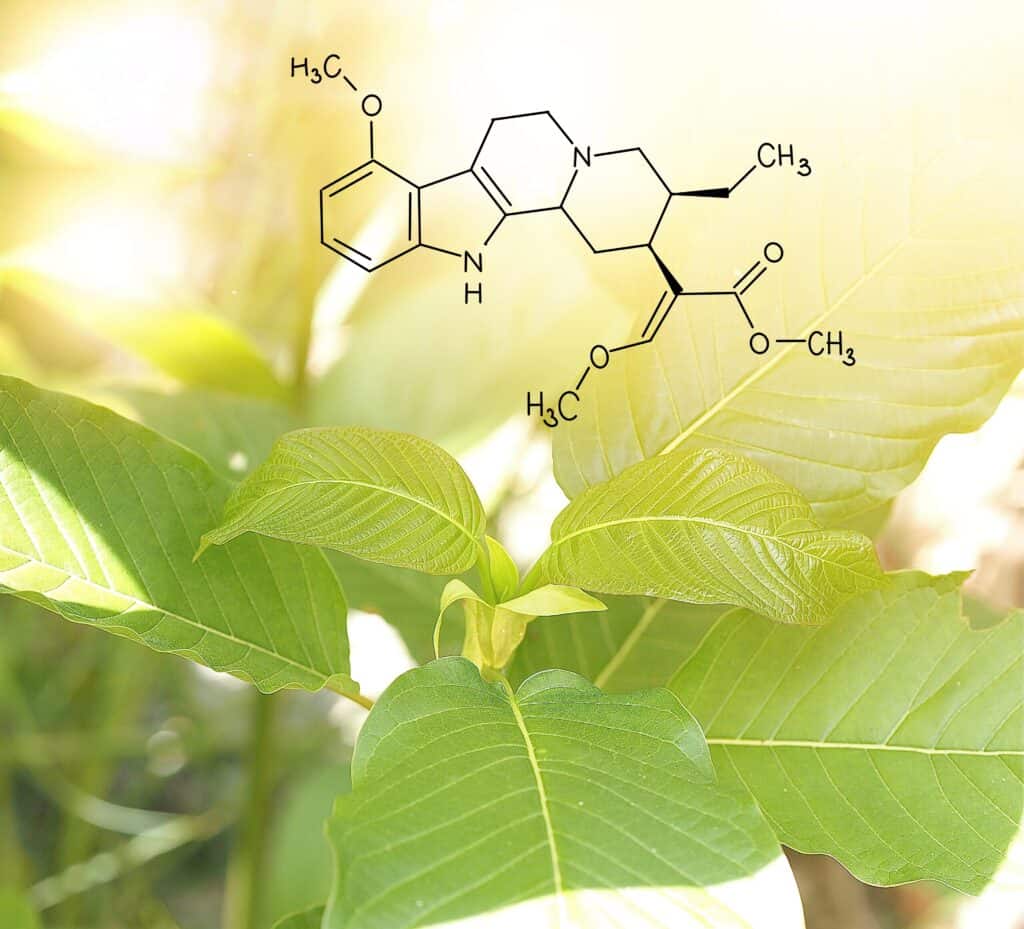

Nearly all of the kratom in the United States comes from Indonesia. Because of the warm tropical climate and rich soil, it creates the perfect environment to grow alkaloid-rich kratom. Plus, kratom has been used locally in the region for centuries, so farming techniques have already been put into place.

Humidity and lots of sunlight is imperative for this plant to thrive. This tropical evergreen tree can grow up to 100 feet tall, with vibrant green leaves that are harvested to create the product most know as kratom. The leaves are harvested at different points of maturity which could reflect different vein colors and alkaloid profiles depending on the time of harvest. Kratom vendors typically market vein colors as green, white and red.

Once the leaves are harvested, the farmers will wash and clean the leaves of any debris. Then, they are put on racks to dry, either in direct sunlight or indoors under UV light depending on the farmer’s technique. The color of the kratom can also depend on how long the leaves are dried.

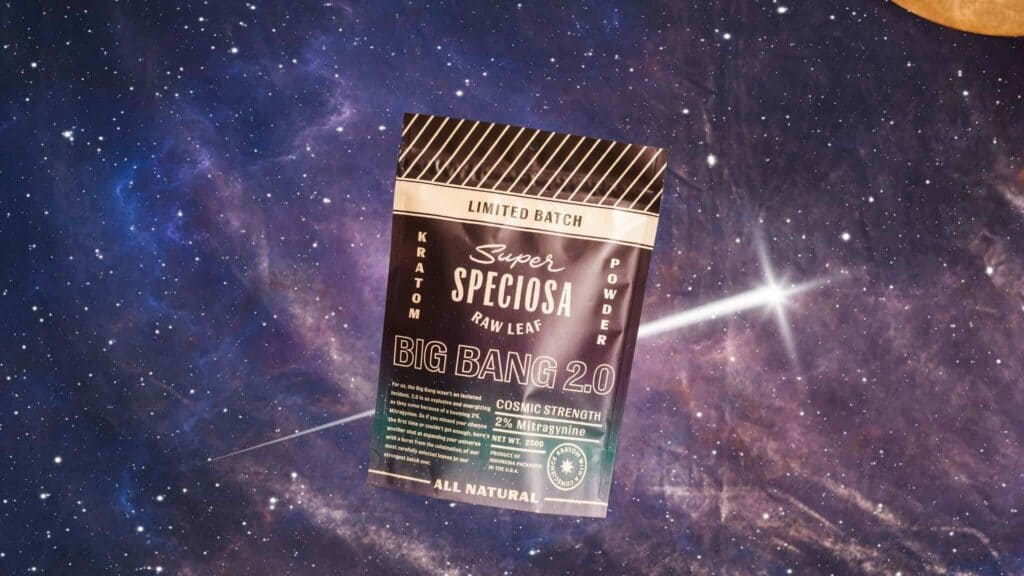

Once the leaves are dried, industrial grinders are used to grind the kratom into a fine powder. Then, the powder is packaged into 1 kg or 25 kg bundles to be shipped off to United States’ ports.

Once the packaged kratom reaches the Super Speciosa warehouse, carefully detailed steps are taken to ensure the product is safe and fully traceable from start to finish.

First, the shipment of kratom is inspected to make sure it has not been tampered with or damaged during shipping. Once the kratom shipment passes inspection, it is accounted for in inventory by assigning a lot number. This begins the traceability process.

The next step is the blending and batching process. The kratom goes through a blender that evenly mixes the product together, and then through a sifter to get any kind of dirt or debris out of the powder. The larger shipment is then broken down into smaller batches and assigned a batch number.

Hot spots of bacteria are common in herbal products. The blending process ensures that the samples sent to the third-party lab test is an accurate portrayal of that batch.

“For testing reasons, we want to mix the [kratom] to get a good representation of the natural product,” explains Reid Barack, Head of Operations. “If we don’t blend it, we don’t really know what we’re testing. We get the product in one giant lot as we call it. When we break down the lot into what we call batches, which is a subset of that lot, we need to make sure that we get the best representation of the product that we’re selling.”

Once the test results come back from the third-party lab, the Quality Control team goes through all the results and makes sure it meets the safety standards of the National Sanitation Foundation.

Once approved, the manufacturing team creates various products like stand-up pouch bags, kratom capsules, kratom teas and kratom tablets.

During the entire course of action, Good Manufacturing Practices (GMP) are followed and strictly enforced to provide safe kratom to Super Speciosa’s customers. The truth is, Indonesia’s kratom farmers don’t have a proper quality assurance process in place. One shipment could contain multiple different blends of kratom, or kratom that has been milled at different times. Super Speciosa’s quality control process has been proven to be safe and effective in order to produce the highest quality products possible.

“The people are the biggest components [of GMP],” says Barack. “Making sure people are properly trained ensures that we are creating a safe and clean product. We go by having good faith. We understand that the product we make is going to be consumed… We want [our employees] to understand that there is no taking shortcuts, they abide by all our procedures and processes. If we start with the people, it will make the procedures and processes easier because we know they are fully trained.”

Documentation is also a crucial part of GMP. Some of the many things that are documented are:

Everything is recorded, and every person is held accountable, every step of the way. These documents are also routinely audited by the American Kratom Association and the FDA.

Super Speciosa has implemented a seamless online ordering system to get kratom shipped out to the customer usually within 24 hours of ordering. The finished kratom product is transferred to the fulfillment warehouse, where packers are working around the clock to make sure the kratom is shipped out in a timely manner. As soon as the customer clicks “Place Order”, their order is sent directly to the fulfillment team and a label is printed. The order is then packed in discreet shipping boxes and picked up by USPS and UPS in the afternoon. The shipping process is so efficient, that all orders placed before 2 pm are shipped the same day.

The customer service department operates Monday through Friday, 9 am to 5 pm est. to handle any issues that may arise before, during or after the ordering process. Emails and phone calls, if missed, are returned within 24 hours. The team responds to all inquiries, and all customers are taken care of.

The systems Super Speciosa sets in place from start to finish, makes them one of the leading companies in the kratom industry.

“What separates us is our relationship. Other people in the industry might purchase their product from an unknown person. We have a great relationship with all our suppliers and growers,” states Barack.

Overall, Super Speciosa is always finding ways to make our process smooth and efficient.

“One of the biggest obstacles in production is that it’s always changing, it is dynamic,” adds Barack. “We have to change our processes, our records, to adapt to our technology, or the needs of the industry or consumer. To resolve it, we go through our records and processes and assess them. We communicate to our quality department and make the proper changes to our policy, procedures, processes, paperwork, anything that is going to make us adapt to that situation. We always want to improve everyday, whether it’s increasing output in a given amount of time, better training, etc. We always are finding ways to be better to enhance our brand and to grow our people.”

These statements and products presented on this website have not been evaluated by the Food and Drug Administration FDA. The products mentioned on this website are not intended to diagnose, prevent, treat or cure any diseases or health conditions. Therefore any information on this website is presented solely as the opinions of their respective authors who in which do not claim in any way shape or form to be medical professionals providing medical advice. SuperSpeciosa.com and its owners or employees cannot be held responsible for, and will not be liable for the inaccuracy or application of any information whatsoever herein provided. By purchasing our products you agree that you are aware and in compliance with your local county, state, or federal regulations. Must be 21 years or older to purchase Kratom. The US FDA has not approved kratom as a dietary supplement. We do not ship to the following states, cities and counties in the US where Kratom is banned: Alabama, Arkansas, Indiana, Rhode Island, Vermont, Wisconsin, Sarasota County, FL, Union County, MS, San Diego, CA, Jerseyville, IL, Oceanside, CA, and Ontario, OR. Furthermore, Kratom is also banned in the following countries where shipment cannot be executed: Australia, Burma, Denmark, Finland, Israel, Lithuania, Malaysia, Myanmar, Poland, Romania, South Korea, Sweden, Thailand, United Kingdom, Vietnam.

This product should be used only as directed on the label. It should not be used if you are pregnant or nursing. Consult with a physician before use if you have a serious medical condition or use prescription medications. A Doctor’s advice should be sought before using this and any supplemental dietary product. All trademarks and copyrights are property of their respective owners and are not affiliated with nor do they endorse this product. By using this site, you agree to follow the Privacy Policy and all Terms & Conditions printed on this site. Void where prohibited by law.

† These statements have not been evaluated by the FDA. This product is not intended to diagnose, treat, cure or prevent any disease.

Testimonials on this website are not intended as claims that our products can be used to diagnose, treat, cure, mitigate or prevent any disease. Read full disclaimer.

By submitting you agree to receive automated promotional messages. This agreement is not a condition of any purchase. See Terms and Privacy Policy. Frequency varies. Can opt out at any time.

There’s always something new happening. Enter your info below to get updates on huge deals, new products and special batch kratom releases.

By submitting you agree to receive automated promotional messages. This agreement is not a condition of any purchase. Message and data rates may apply. See Terms and Privacy Policy. Frequency varies. Can opt out at any time.